Premium Features of Our Raw Aluminium Profiles

Consistent Quality

Our raw aluminium profiles undergo rigorous quality checks ensuring consistent dimensions, uniform alloy composition, and superior surface finish for reliable fabrication outcomes.

Grade Versatility

We supply various aluminium alloy grades including 6061, 6063, and 6005 series, each optimized for specific applications from architectural to industrial requirements.

Custom Extrusions

Beyond standard profiles, we offer custom extrusion services with precise dimensional tolerances and specialized shapes tailored to unique project specifications.

Bulk Supply Capacity

With efficient supply chain management, we can handle large volume orders while maintaining timely delivery schedules and competitive pricing for bulk requirements.

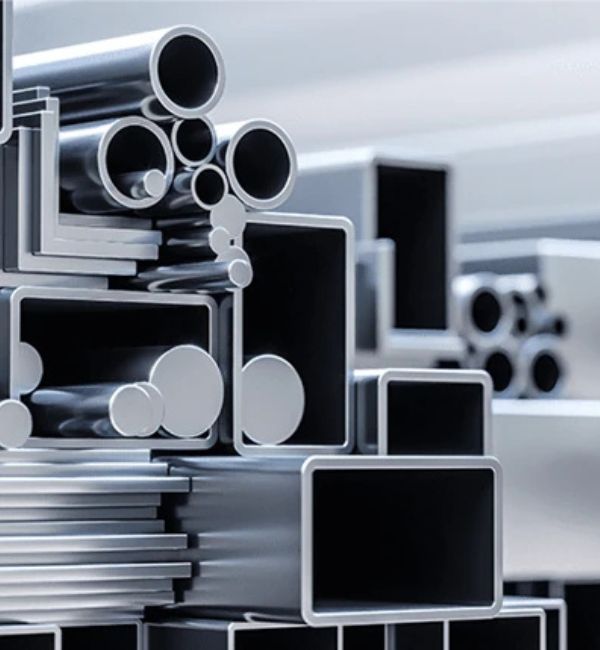

Premium Raw Aluminium Profiles & Sections

At Aluvate, we supply high-quality raw aluminium profiles, sections, and extrusions that form the foundation for superior fabrication work. Sourced from trusted manufacturers and processed to exacting standards, our aluminium materials offer excellent workability, consistent quality, and reliable performance. Whether you're a window manufacturer, architectural fabricator, or industrial supplier, our raw aluminium products provide the perfect starting point for creating durable, precise, and aesthetically pleasing end products.

Technical Questions About Raw Aluminium Materials

Understanding material specifications and properties is crucial for successful fabrication. Here are answers to common technical questions about our raw aluminium products to help you select the right materials for your projects.

At Aluvate, we provide comprehensive technical support to help fabricators and manufacturers choose the most suitable aluminium materials. Our team can assist with alloy selection, technical specifications, and application guidance to ensure optimal results for your specific requirements.